Molette's 14" (35cm) Home Made Metal Wheel

May 19, 2014 16:38:05 GMT

natnat899, mick, and 1 more like this

Post by moletteuk on May 19, 2014 16:38:05 GMT

This is the fourth metal degu running wheel I have made and it’s definitely the best so far. Here's how to make it:

The wheel part is made from a Windsor heavy duty 14” by 4.5” cake tin. www.windsorcakecraft.co.uk/14_inch_round_tin_1.html?category_id=0&search_string=14%22+round+tin

Other potential tins include a 14 inch anodised version by PME which can be bought on various sites such as amazon, ebay and dedicated bakeware companies.

www.pmecake.co.uk/professional-bakeware-pans/5088-4inch-deep-round-cak-pans.html#/4inch_deep_round_cak-14x4_3556x1016cm

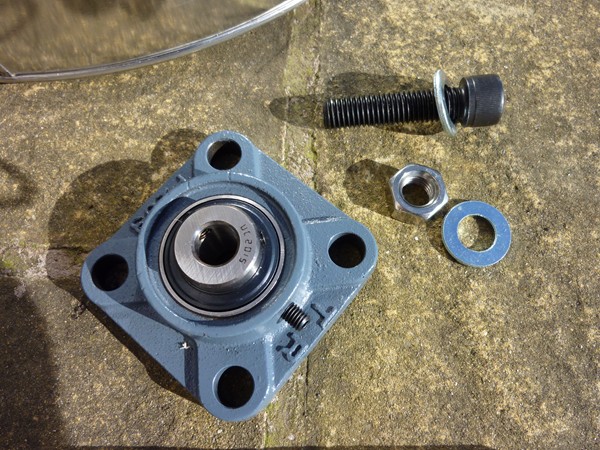

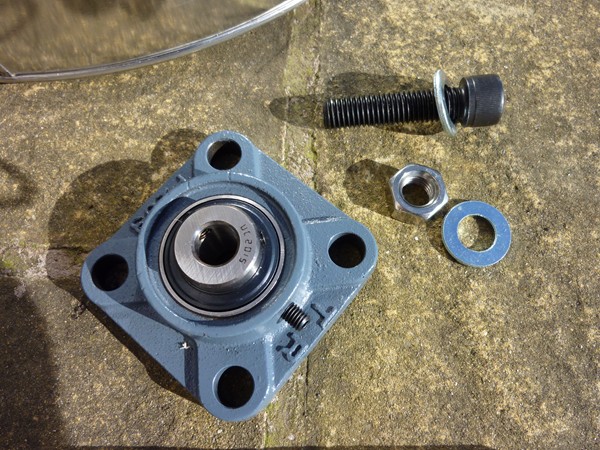

I used a 12mm 4 bolt flange bearing like this, but they are cheaper on ebay: www.bearing-king.co.uk/bearing/ucf201-budget-brand/5649

Please note you will need a 12 or even 13mm metal drill bit or ‘stepped cone’ drill or a 10mm drill and a circular file to make a suitable hole in the tin to fit the main bolt for the 12mm bearing. You may wish to look for a bearing that takes a smaller diameter bolt if you need to avoid this.

You will also need:

4 nuts & bolts with 8 washers to fix bearing in place.

1 x 12mm nut & bolt and washers to fix bearing to wheel.

Optional plank of wood to go between rear of bearing and cage with screws.

Close up of bearing with main central nut and bolt.

Basically, you fix the bearing to the cage using the 4 outer holes in the bearing and then drill a hole in the middle of the tin and attach it to the inner moving part of the bearing with a large bolt.

We decided to use a plank of wood between the bearing and the cage so we could attach this with smaller woodscrews rather than large bolts and it would come off and on more easily just from the front this way.

First of all, drill a large hole in the middle of the plank big enough to easily pass through the washer and nut that go with the 12mm bolt, this is just an access hole.

Then drill 4 holes corresponding to the holes in the corners of the bearing. In the back of your plank, make wide countersink recesses around the 4 holes, big enough to take the washer and nut so they won’t stick out further than the back of the plank.

(If you don't want to use the plank and want to attach the bearing straight to the cage, you don't need to make the recesses, just make plain holes direct in the cage big enough to take the four corner bolts).

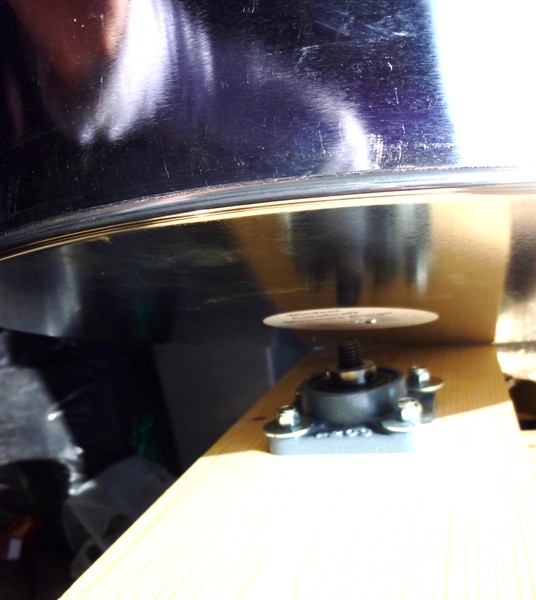

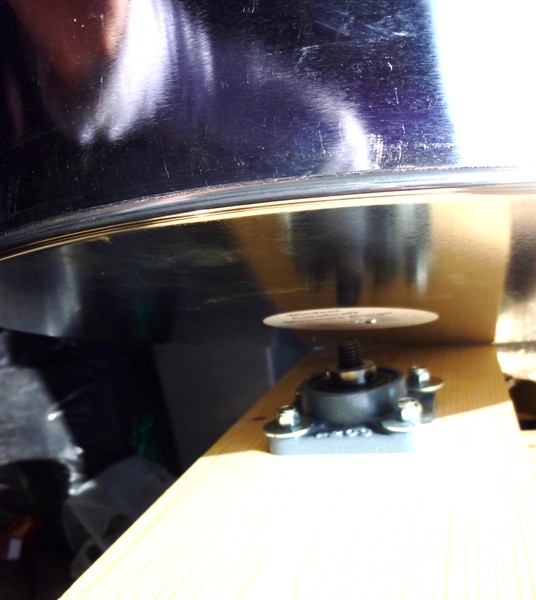

Attach the bearing to the plank with nuts, bolts and washers (shown in photo above), I think we used 6 or 8mm bolts, we only used such big washers because that is what we had to hand.

Rear view, nothing projects beyond the back of the plank so the plank will sit flat against the cage.

(Note photo below shows middle nut and bolt already in place even though they need unfastening again to fit the wheel)

Find the middle of your cake tin and drill a suitable hole through. Clean up the hole with a file. Fit 12mm bolt right through the middle of the bearing and cake tin, fasten with washers and nut.

To make it ultra quiet you may wish to reinforce the back of the tin with a piece of 6mm mdf or extra sheet of metal. Just cut to size, drill central hole and clamp with main bolt flush against back of tin as you add the tin (you could glue or screw it to the tin for even more stiffness). We used a circle approx 2/3 the diameter of the tin. Make sure any mdf isn’t accessible for chewing.

Attach plank with completed wheel to cage. We pre-drilled holes in the corners of the plank, put pilot holes in the side of the cage and screwed it on.

A couple of months on I have noticed that some of the plating is wearing away on the wheel, so I have bought some Plasti-Kote fast dry enamel (child safe) to treat it with, but I haven't got this done yet.

Video

My girls love it!

The wheel part is made from a Windsor heavy duty 14” by 4.5” cake tin. www.windsorcakecraft.co.uk/14_inch_round_tin_1.html?category_id=0&search_string=14%22+round+tin

Other potential tins include a 14 inch anodised version by PME which can be bought on various sites such as amazon, ebay and dedicated bakeware companies.

www.pmecake.co.uk/professional-bakeware-pans/5088-4inch-deep-round-cak-pans.html#/4inch_deep_round_cak-14x4_3556x1016cm

I used a 12mm 4 bolt flange bearing like this, but they are cheaper on ebay: www.bearing-king.co.uk/bearing/ucf201-budget-brand/5649

Please note you will need a 12 or even 13mm metal drill bit or ‘stepped cone’ drill or a 10mm drill and a circular file to make a suitable hole in the tin to fit the main bolt for the 12mm bearing. You may wish to look for a bearing that takes a smaller diameter bolt if you need to avoid this.

You will also need:

4 nuts & bolts with 8 washers to fix bearing in place.

1 x 12mm nut & bolt and washers to fix bearing to wheel.

Optional plank of wood to go between rear of bearing and cage with screws.

Close up of bearing with main central nut and bolt.

Basically, you fix the bearing to the cage using the 4 outer holes in the bearing and then drill a hole in the middle of the tin and attach it to the inner moving part of the bearing with a large bolt.

We decided to use a plank of wood between the bearing and the cage so we could attach this with smaller woodscrews rather than large bolts and it would come off and on more easily just from the front this way.

First of all, drill a large hole in the middle of the plank big enough to easily pass through the washer and nut that go with the 12mm bolt, this is just an access hole.

Then drill 4 holes corresponding to the holes in the corners of the bearing. In the back of your plank, make wide countersink recesses around the 4 holes, big enough to take the washer and nut so they won’t stick out further than the back of the plank.

(If you don't want to use the plank and want to attach the bearing straight to the cage, you don't need to make the recesses, just make plain holes direct in the cage big enough to take the four corner bolts).

Attach the bearing to the plank with nuts, bolts and washers (shown in photo above), I think we used 6 or 8mm bolts, we only used such big washers because that is what we had to hand.

Rear view, nothing projects beyond the back of the plank so the plank will sit flat against the cage.

(Note photo below shows middle nut and bolt already in place even though they need unfastening again to fit the wheel)

Find the middle of your cake tin and drill a suitable hole through. Clean up the hole with a file. Fit 12mm bolt right through the middle of the bearing and cake tin, fasten with washers and nut.

To make it ultra quiet you may wish to reinforce the back of the tin with a piece of 6mm mdf or extra sheet of metal. Just cut to size, drill central hole and clamp with main bolt flush against back of tin as you add the tin (you could glue or screw it to the tin for even more stiffness). We used a circle approx 2/3 the diameter of the tin. Make sure any mdf isn’t accessible for chewing.

Attach plank with completed wheel to cage. We pre-drilled holes in the corners of the plank, put pilot holes in the side of the cage and screwed it on.

A couple of months on I have noticed that some of the plating is wearing away on the wheel, so I have bought some Plasti-Kote fast dry enamel (child safe) to treat it with, but I haven't got this done yet.

Video

My girls love it!