Post by krazypara3165 on Sept 29, 2015 8:01:42 GMT

Morning all!

Last night I started my cage build...... This thread is not an all inclusive "how to" but more of how I have done things (right and wrong) so we can learn from my mistakes, and get a rough idea of the process of building a cage. for the record the limitations of my wood working skills are building planters and that's about it! so consider me pretty much a novice!

I welcome all critique (good and bad) and welcome anyone chiming in with better practices!

I will also include parts and costs and best places for materials (UK only)

So we begin!

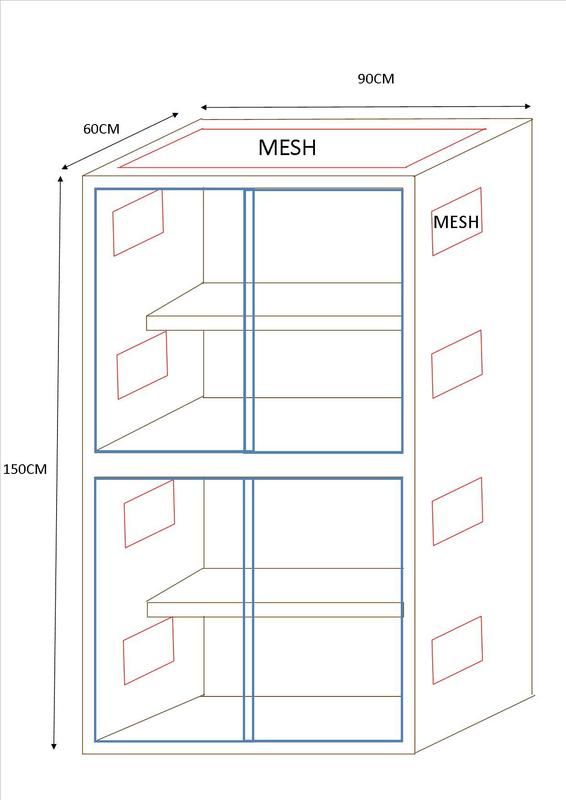

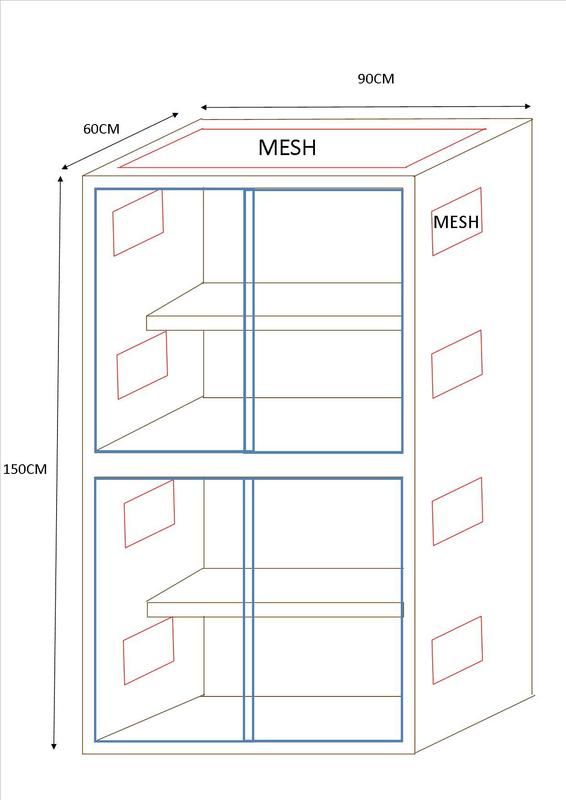

Here is a rough design of what I was looking to create:

I started with with working out the costs!

Plywood £50

Additional timber £10

Glass £50

Glass runners £10

Metal strip £10

Metal edging strip £10

Vinyl £10

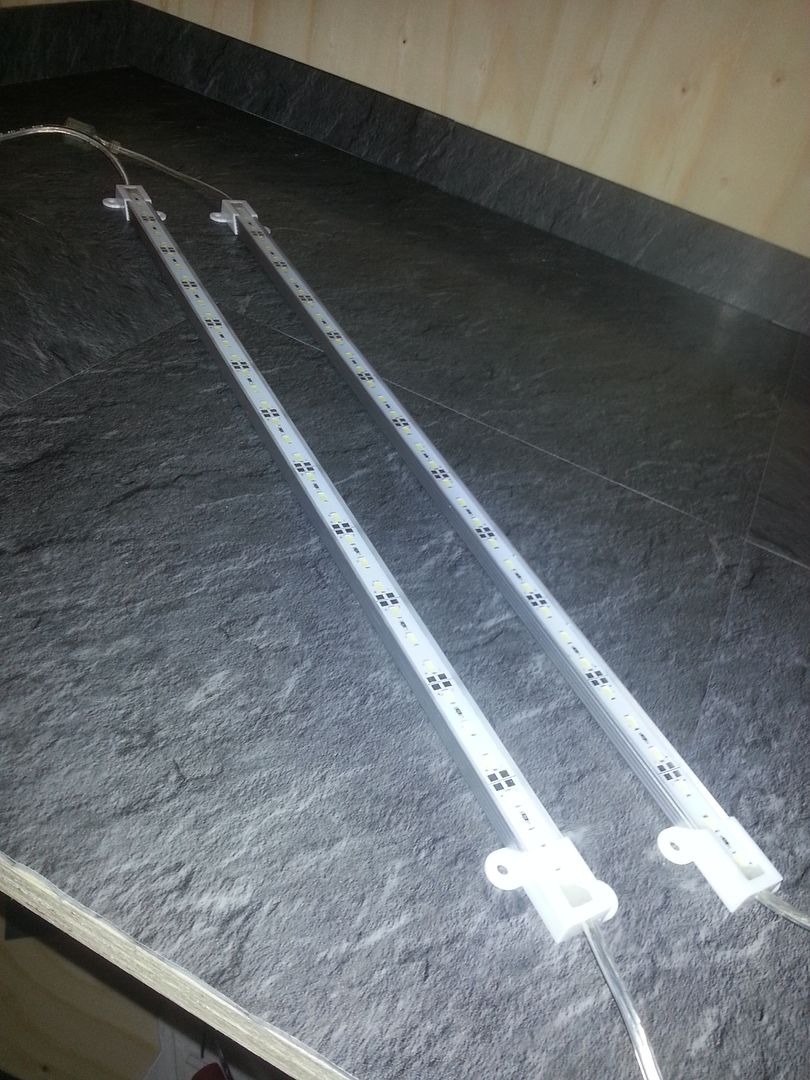

Mesh £10

Total £160

I then started my meticulous planning. someone has always told me with timber, measure twice, cut once. Sadly, The measurements I had started with were wrong to begin with!

My cage dimensions are just under the recommended size, the reason being is a combination of the space that the cage is going into and partly because any larger and I would have to spend Another £25 on timber which would leave a lot of waste.

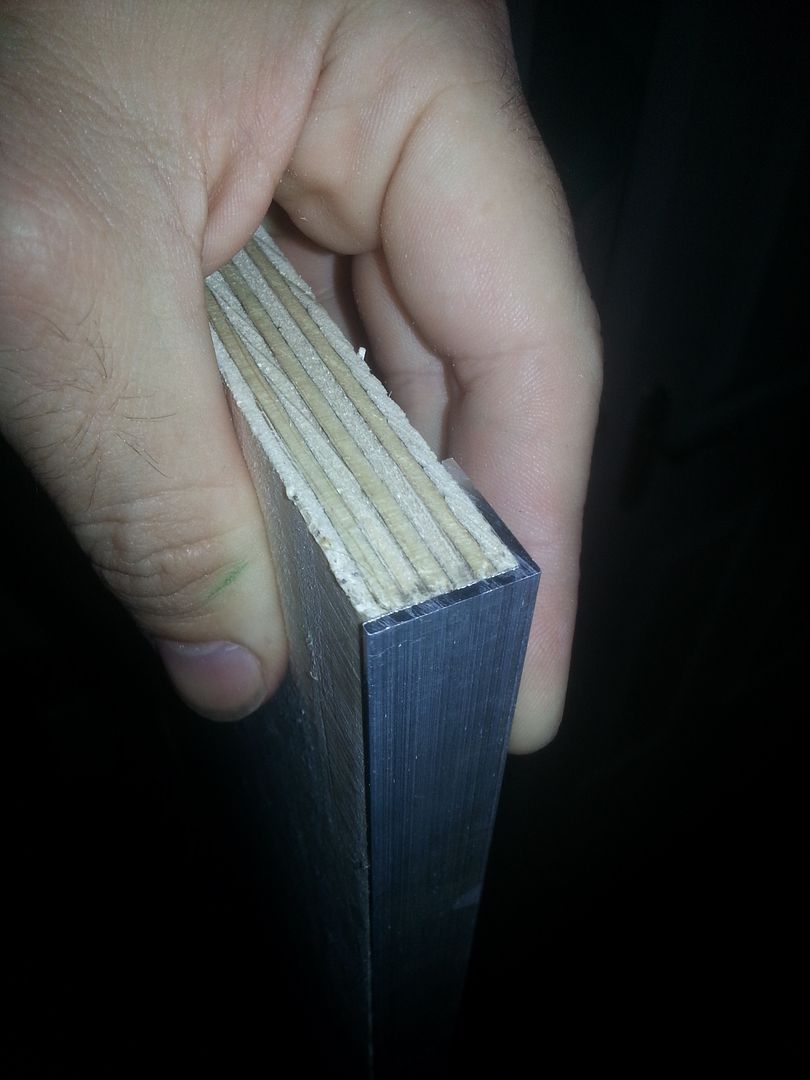

The wood I chose was Wickes 18x1220x2440 spruce structural plywood.

www.wickes.co.uk/Wickes-Structural-Spruce-Plywood-18x1220x2440mm/p/110036

I chose this as its easy to cut and looks a lot better than most plywood it also stains and take paint rather well. Downsides are it is softwood (so easier to chew) but any plywood that is more than 12mm thick should do.

On a bit of a side note I have table mitre saw, whilst its great, its useless for this. I treated myself to a handheld circular saw from B and Q £40 and it does a great job www.diy.com/departments/mac-allister-1200w-165mm-circular-saw-mscs1200/592966_BQ.prd

So then I had to work out the cuts.... I have 2 sheets of wood 1220x2440mm.

The first one was cut into the two sides (each side was 1500x600) and the two floors (originally 900x600 but later reduced the width by 36mm more on this later!) That near enough used the first board with very little waste.

The second board was more complex. I cut the back wall (1550x900) and the two 3/4 shelves (400x900) this has left me with a few cuts that I will use as an unplanned second shelf for the top compartment or I will change the design for the top (so far I'm planning on just throwing a sheet of mesh over the top but Ill see how it goes.)

MISTAKE NUMBER 1!

The walls and back should of been built on top of the base. Instead they were screwed to the side this meant I cannot put the cage on casters as because the walls and back are screwed into the ply base it would split and fall apart under the weight.

MISTAKE NUMBER 2

If I screw the panels onto the side of the base it meant that the back panel was now 36mm too short at the sides!

MISTAKE NUMBER 3

To rectify the above issue I removed 36mm from the with of all the floors and shelfs - job done I thought..... It did work but there was a better way....

WHAT I SHOULD OF DONE....

I should of trimmed the width of the two side panels by 36mm therefore the walls and the rear could of been built up on top of the base rather than screwed into the sides!

(the base issue will be rectified with additional support and casters at a later date)

So far this is where I am....

I need to cut out the 'hatch' in the shelves and fit them in and drill a hatch into the middle floor but I am leaving this until I can find a suitable way of closing the gap as for emergencies I want to be able to split the sections.

More updates to come in the following weeks!

Last night I started my cage build...... This thread is not an all inclusive "how to" but more of how I have done things (right and wrong) so we can learn from my mistakes, and get a rough idea of the process of building a cage. for the record the limitations of my wood working skills are building planters and that's about it! so consider me pretty much a novice!

I welcome all critique (good and bad) and welcome anyone chiming in with better practices!

I will also include parts and costs and best places for materials (UK only)

So we begin!

Here is a rough design of what I was looking to create:

I started with with working out the costs!

Plywood £50

Additional timber £10

Glass £50

Glass runners £10

Metal strip £10

Metal edging strip £10

Vinyl £10

Mesh £10

Total £160

I then started my meticulous planning. someone has always told me with timber, measure twice, cut once. Sadly, The measurements I had started with were wrong to begin with!

My cage dimensions are just under the recommended size, the reason being is a combination of the space that the cage is going into and partly because any larger and I would have to spend Another £25 on timber which would leave a lot of waste.

The wood I chose was Wickes 18x1220x2440 spruce structural plywood.

www.wickes.co.uk/Wickes-Structural-Spruce-Plywood-18x1220x2440mm/p/110036

I chose this as its easy to cut and looks a lot better than most plywood it also stains and take paint rather well. Downsides are it is softwood (so easier to chew) but any plywood that is more than 12mm thick should do.

On a bit of a side note I have table mitre saw, whilst its great, its useless for this. I treated myself to a handheld circular saw from B and Q £40 and it does a great job www.diy.com/departments/mac-allister-1200w-165mm-circular-saw-mscs1200/592966_BQ.prd

So then I had to work out the cuts.... I have 2 sheets of wood 1220x2440mm.

The first one was cut into the two sides (each side was 1500x600) and the two floors (originally 900x600 but later reduced the width by 36mm more on this later!) That near enough used the first board with very little waste.

The second board was more complex. I cut the back wall (1550x900) and the two 3/4 shelves (400x900) this has left me with a few cuts that I will use as an unplanned second shelf for the top compartment or I will change the design for the top (so far I'm planning on just throwing a sheet of mesh over the top but Ill see how it goes.)

MISTAKE NUMBER 1!

The walls and back should of been built on top of the base. Instead they were screwed to the side this meant I cannot put the cage on casters as because the walls and back are screwed into the ply base it would split and fall apart under the weight.

MISTAKE NUMBER 2

If I screw the panels onto the side of the base it meant that the back panel was now 36mm too short at the sides!

MISTAKE NUMBER 3

To rectify the above issue I removed 36mm from the with of all the floors and shelfs - job done I thought..... It did work but there was a better way....

WHAT I SHOULD OF DONE....

I should of trimmed the width of the two side panels by 36mm therefore the walls and the rear could of been built up on top of the base rather than screwed into the sides!

(the base issue will be rectified with additional support and casters at a later date)

So far this is where I am....

I need to cut out the 'hatch' in the shelves and fit them in and drill a hatch into the middle floor but I am leaving this until I can find a suitable way of closing the gap as for emergencies I want to be able to split the sections.

More updates to come in the following weeks!

You've really highlighted that the trickiest part of a cage build is visualising the connections and overlaps and taking account of this before you cut.

You've really highlighted that the trickiest part of a cage build is visualising the connections and overlaps and taking account of this before you cut.